THE BEST MATERIAL FOR A STONE COUNTERTOP

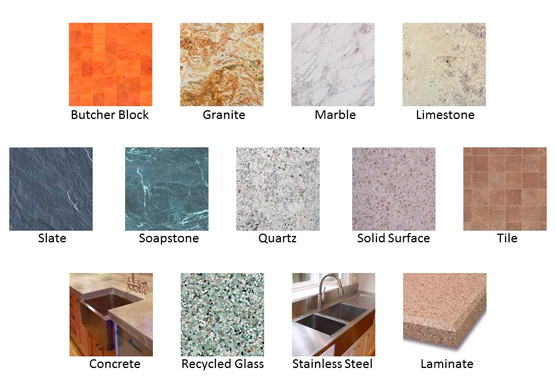

The best material for a stone countertop depends on your individual needs and preferences. Here are some popular materials and their characteristics:

Granite: Granite is a classic and durable option for stone countertops. It is heat, scratch and stain resistant when properly sealed. Granite offers a wide variety of natural colors and patterns, making it a versatile choice for many different design styles.

Marble: Marble is known for its beauty and elegance. It has a distinctive and unique look with natural veining and patterns. However, marble is more porous than granite and can be prone to staining and scratching. It requires regular maintenance and sealing to preserve its appearance.

Quartz: Engineered quartz, also known as composite quartz, is a popular choice for stone countertops. It is composed of natural quartz particles mixed with resins and pigments. Engineered quartz is highly resistant to stains, scratches and heat. Plus, it offers a wide variety of colors and patterns, including options that mimic the look of marble or granite.

Granite: Granite is a classic and durable option for stone countertops. It is heat, scratch and stain resistant when properly sealed. Granite offers a wide variety of natural colors and patterns, making it a versatile choice for many different design styles.

Marble: Marble is known for its beauty and elegance. It has a distinctive and unique look with natural veining and patterns. However, marble is more porous than granite and can be prone to staining and scratching. It requires regular maintenance and sealing to preserve its appearance.

Quartz: Engineered quartz, also known as composite quartz, is a popular choice for stone countertops. It is composed of natural quartz particles mixed with resins and pigments. Engineered quartz is highly resistant to stains, scratches and heat. Plus, it offers a wide variety of colors and patterns, including options that mimic the look of marble or granite.

Soapstone: is a material that is soft to the touch and has a distinctive, rustic appearance. It is resistant to heat and stains, although it can be scratched more easily than granite or quartz. Soapstone takes on a beautiful aging as it darkens over time and can be renewed with mineral oil.

Limestone: is a less common choice, but offers natural beauty and a smooth feel. However, limestone is more porous than granite or quartz and may require regular sealing to prevent staining and damage.

Dekton: It is composed of a proprietary blend of inorganic materials, including glass, porcelain and quartz. This manufacturing process uses a technology called Particle Sintering Technology (TSP), which subjects materials to high temperatures and pressures to create a durable and resistant surface.

It is important to consider factors such as resistance to heat, stains and scratches, required maintenance and desired aesthetics when selecting the material for your stone countertop. It is also advisable to consult with a professional in design or in the installation of countertops to obtain specific advice based on your needs and budget.

Limestone: is a less common choice, but offers natural beauty and a smooth feel. However, limestone is more porous than granite or quartz and may require regular sealing to prevent staining and damage.

Dekton: It is composed of a proprietary blend of inorganic materials, including glass, porcelain and quartz. This manufacturing process uses a technology called Particle Sintering Technology (TSP), which subjects materials to high temperatures and pressures to create a durable and resistant surface.

It is important to consider factors such as resistance to heat, stains and scratches, required maintenance and desired aesthetics when selecting the material for your stone countertop. It is also advisable to consult with a professional in design or in the installation of countertops to obtain specific advice based on your needs and budget.

The importance of having adequate equipment to cut dekton and porcelain

Dekton, among other alternative stone materials, continues to grow in popularity for applications such as countertops, flooring, and both interior and exterior wall cladding. Being a hard dense product, it is crucial to use appropriate tooling during the fabrication process. Carlos Sustaita, production director for STA Granite, provides several important tips of advice for those working with compact sintered stone.

Why do products such as Dekton need special/different tools than those that are used for cutting granite and marble?

Material hardness is the key to understanding why you need different tools to fabricate Dekton. The material has a

very high density (ultra-compact), which means that if you don’t use proper tools, you can either break the tool or the material or even worse, damage the machinery.

The cutting process requires trimming the edges to release tensions. Then you have to follow cutting recommendations, which include using plenty of water, the proper speed, feed rate, etc. Once you follow the rules, it’s a piece of cake.

When doing edging on Dekton, What is the difference in the process compared to a natural stone?

In this sense, Dekton’s edge is very easy to work with since the material is very homogeneous, and it is easy to get very good results. Any fabricator can do it well on the first attempt.

What are some common mistakes that fabricators are making when it comes to cutting this material? And, what are some common mistakes with doing edging or doing sinkholes or something?

The main mistake is trying to fabricate Dekton as if it was a granite or quartz composite. You will fail if you use the same tools, speed rates, and so on. Another common mistake is trying to cut Dekton in uneven support. It is a common source of problems too.

Sometimes people ask about what machine is best to cut Dekton. I believe the key is not the machine but the tools and proper maintenance. I have seen people with very modest equipment doing amazing things and the other way around.

7 Keys for Cutting Ultra-Compact and Sintered Dekton and Porcelain Materials

1. Water

It may seem too simple or too intuitive to matter, but less than adequate water AND hoses positioned incorrectly is the most common error causing headaches among cutting these materials.

It may seem too simple or too intuitive to matter, but less than adequate water AND hoses positioned incorrectly is the most common error causing headaches among cutting these materials.

2. Check your table level

One of the more overlooked aspects of successful cutting is, to the degree that your table is not level in the horizontal plane, vibrations will occur. This unevenness can result in chipping and likely breaking the edge of your slab.

One of the more overlooked aspects of successful cutting is, to the degree that your table is not level in the horizontal plane, vibrations will occur. This unevenness can result in chipping and likely breaking the edge of your slab.

3. Buy the right blade

As cliche, as it may sound, choosing the right blade for the material you are processing, is critical.

As cliche, as it may sound, choosing the right blade for the material you are processing, is critical.

4. Removing tensioning strips

While each manufacturer of ultra-compact and sintered porcelain materials may, or may not have tensioning strips built into the perimeters of each slab, if they are not removed before cutting, the slab is at higher risk of cracking or breaking.

While each manufacturer of ultra-compact and sintered porcelain materials may, or may not have tensioning strips built into the perimeters of each slab, if they are not removed before cutting, the slab is at higher risk of cracking or breaking.

5. Feed rate and RPMs

Using the same feed rate and RPMs you may be accustomed to when cutting other materials can be a recipe for trouble. Unlike fabricating more common materials such as marble and granite, we’ve seen the most success cutting ultra-compact and sintered porcelain materials when following a systemized approach is used.

Using the same feed rate and RPMs you may be accustomed to when cutting other materials can be a recipe for trouble. Unlike fabricating more common materials such as marble and granite, we’ve seen the most success cutting ultra-compact and sintered porcelain materials when following a systemized approach is used.

6. Avoiding Plunging

While plunge cutting tends to be of little concern for most sawyers when cutting ultra-compact and sintered porcelain materials it can pose big problems resulting in cracking or breaking your slab.

While plunge cutting tends to be of little concern for most sawyers when cutting ultra-compact and sintered porcelain materials it can pose big problems resulting in cracking or breaking your slab.

7. Cutting Sinks

Projects requiring a sink cut-out can be an obstacle many fabricators dread. Since we already know plunging is not the ideal way to go about this, what are your options? When preparing a sink cut-out, it is advised to drill each of the four corners with a 1/2” core bit before to start initiating cutting.

Projects requiring a sink cut-out can be an obstacle many fabricators dread. Since we already know plunging is not the ideal way to go about this, what are your options? When preparing a sink cut-out, it is advised to drill each of the four corners with a 1/2” core bit before to start initiating cutting.

PORCELAIN FOR YOUR HOME, TILES

Ceramic tiles are thin pieces made of clay, silica, fluxes, dyes, and other raw materials to create floors and/or walls.…

Read More

PORCELAIN FOR YOUR HOME, COUNTERTOPS FOR YOUR KITCHEN

Due to its great demand, porcelain kitchen countertops are becoming more sophisticated and have greater hardness

Read More

DEKTON FOR YOUR HOME, FLOORS, AND PAVEMENTS

Large format and minimal joints. Dekton allows you to create outdoor and indoor floors with great visual continuity and maximum…

Read More

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34