THE MOST POPULAR DEKTON COUNTERTOP COLORS OF 2023 PART 1

Dekton is mainly composed of mixtures of glass, porcelain, and quartz, which are subjected to a high-tech process called Particle Sintering Technology (TSP). This process uses a combination of heat and pressure to create an ultra-compact and strong material.

Dekton surfaces are characterized by having exceptional properties, such as high resistance to scratches, heat, stains, and fading. In addition, they are very durable and can be used both indoors and outdoors, as they are resistant to UV rays and humidity.

Dekton is used in a wide range of applications, including kitchen countertops, wall cladding, flooring, building facades, and furniture. It is available in a variety of colors, textures, and finishes, allowing for great versatility and design options.

In summary, Dekton is a highly resistant and durable surface material used in architectural and interior design applications, known for its exceptional properties and wide range of design options.

Dekton surfaces are characterized by having exceptional properties, such as high resistance to scratches, heat, stains, and fading. In addition, they are very durable and can be used both indoors and outdoors, as they are resistant to UV rays and humidity.

Dekton is used in a wide range of applications, including kitchen countertops, wall cladding, flooring, building facades, and furniture. It is available in a variety of colors, textures, and finishes, allowing for great versatility and design options.

In summary, Dekton is a highly resistant and durable surface material used in architectural and interior design applications, known for its exceptional properties and wide range of design options.

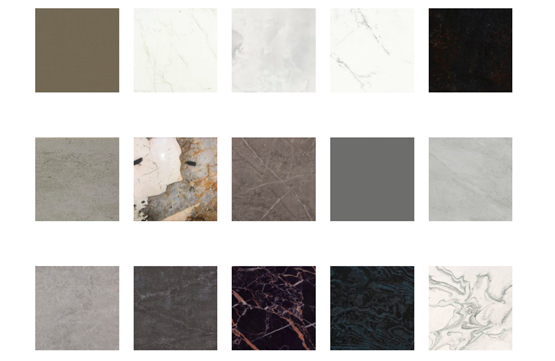

Dekton offers a wide range of colors and finishes to suit different styles and design preferences. Next, I will mention some of the popular Dekton series and colors:

Natural Collection Series: This series is inspired by the beauty and authenticity of natural stones. Some standout colors in this series include:

• Aura: A pure white color with subtle gray veins and an elegant, luminous appearance.

• Nilium: A soft silver tone that evokes the look of polished metal.

• Bergen: A gray color with warm undertones that simulate the look of natural stone.

Industrial Collection Series: This series is inspired by industrial and urban materials, creating surfaces with a modern and resistant appearance. Some notable colors in this series are:

• Trillium: A dark shade that mimics the look of rusty steel with its combination of grays and browns.

• Radium: A black color with bluish undertones and textures that evoke the look of concrete.

• Orix: A dark gray shade with subtle brown-toned veining and a rough texture reminiscent of aged concrete.

Natural Collection Series: This series is inspired by the beauty and authenticity of natural stones. Some standout colors in this series include:

• Aura: A pure white color with subtle gray veins and an elegant, luminous appearance.

• Nilium: A soft silver tone that evokes the look of polished metal.

• Bergen: A gray color with warm undertones that simulate the look of natural stone.

Industrial Collection Series: This series is inspired by industrial and urban materials, creating surfaces with a modern and resistant appearance. Some notable colors in this series are:

• Trillium: A dark shade that mimics the look of rusty steel with its combination of grays and browns.

• Radium: A black color with bluish undertones and textures that evoke the look of concrete.

• Orix: A dark gray shade with subtle brown-toned veining and a rough texture reminiscent of aged concrete.

Solid Collection Series: This series offers solid and uniform colors, ideal for creating minimalist and elegant spaces. Some standout colors in this series include:

• Halo: A pure and brilliant white that brings luminosity and clarity to spaces.

• Zenith: An intense and sophisticated black color, perfect for modern and avant-garde environments.

• Domoos: A medium gray shade that combines versatility and elegance in one color.

These are just a few examples of the wide range of colors that Dekton offers. The brand continues to innovate and release new series and colors regularly, so there are always up-to-date options available to suit the needs and tastes of designers and consumers.

• Halo: A pure and brilliant white that brings luminosity and clarity to spaces.

• Zenith: An intense and sophisticated black color, perfect for modern and avant-garde environments.

• Domoos: A medium gray shade that combines versatility and elegance in one color.

These are just a few examples of the wide range of colors that Dekton offers. The brand continues to innovate and release new series and colors regularly, so there are always up-to-date options available to suit the needs and tastes of designers and consumers.

The importance of having adequate equipment to cut dekton and porcelain

Dekton, among other alternative stone materials, continues to grow in popularity for applications such as countertops, flooring, and both interior and exterior wall cladding. Being a hard dense product, it is crucial to use appropriate tooling during the fabrication process. Carlos Sustaita, production director for STA Granite, provides several important tips of advice for those working with compact sintered stone.

Why do products such as Dekton need special/different tools than those that are used for cutting granite and marble?

Material hardness is the key to understanding why you need different tools to fabricate Dekton. The material has a

very high density (ultra-compact), which means that if you don’t use proper tools, you can either break the tool or the material or even worse, damage the machinery.

The cutting process requires trimming the edges to release tensions. Then you have to follow cutting recommendations, which include using plenty of water, the proper speed, feed rate, etc. Once you follow the rules, it’s a piece of cake.

When doing edging on Dekton, What is the difference in the process compared to a natural stone?

In this sense, Dekton’s edge is very easy to work with since the material is very homogeneous, and it is easy to get very good results. Any fabricator can do it well on the first attempt.

What are some common mistakes that fabricators are making when it comes to cutting this material? And, what are some common mistakes with doing edging or doing sinkholes or something?

The main mistake is trying to fabricate Dekton as if it was a granite or quartz composite. You will fail if you use the same tools, speed rates, and so on. Another common mistake is trying to cut Dekton in uneven support. It is a common source of problems too.

Sometimes people ask about what machine is best to cut Dekton. I believe the key is not the machine but the tools and proper maintenance. I have seen people with very modest equipment doing amazing things and the other way around.

7 Keys for Cutting Ultra-Compact and Sintered Dekton and Porcelain Materials

1. Water

It may seem too simple or too intuitive to matter, but less than adequate water AND hoses positioned incorrectly is the most common error causing headaches among cutting these materials.

It may seem too simple or too intuitive to matter, but less than adequate water AND hoses positioned incorrectly is the most common error causing headaches among cutting these materials.

2. Check your table level

One of the more overlooked aspects of successful cutting is, to the degree that your table is not level in the horizontal plane, vibrations will occur. This unevenness can result in chipping and likely breaking the edge of your slab.

One of the more overlooked aspects of successful cutting is, to the degree that your table is not level in the horizontal plane, vibrations will occur. This unevenness can result in chipping and likely breaking the edge of your slab.

3. Buy the right blade

As cliche, as it may sound, choosing the right blade for the material you are processing, is critical.

As cliche, as it may sound, choosing the right blade for the material you are processing, is critical.

4. Removing tensioning strips

While each manufacturer of ultra-compact and sintered porcelain materials may, or may not have tensioning strips built into the perimeters of each slab, if they are not removed before cutting, the slab is at higher risk of cracking or breaking.

While each manufacturer of ultra-compact and sintered porcelain materials may, or may not have tensioning strips built into the perimeters of each slab, if they are not removed before cutting, the slab is at higher risk of cracking or breaking.

5. Feed rate and RPMs

Using the same feed rate and RPMs you may be accustomed to when cutting other materials can be a recipe for trouble. Unlike fabricating more common materials such as marble and granite, we’ve seen the most success cutting ultra-compact and sintered porcelain materials when following a systemized approach is used.

Using the same feed rate and RPMs you may be accustomed to when cutting other materials can be a recipe for trouble. Unlike fabricating more common materials such as marble and granite, we’ve seen the most success cutting ultra-compact and sintered porcelain materials when following a systemized approach is used.

6. Avoiding Plunging

While plunge cutting tends to be of little concern for most sawyers when cutting ultra-compact and sintered porcelain materials it can pose big problems resulting in cracking or breaking your slab.

While plunge cutting tends to be of little concern for most sawyers when cutting ultra-compact and sintered porcelain materials it can pose big problems resulting in cracking or breaking your slab.

7. Cutting Sinks

Projects requiring a sink cut-out can be an obstacle many fabricators dread. Since we already know plunging is not the ideal way to go about this, what are your options? When preparing a sink cut-out, it is advised to drill each of the four corners with a 1/2” core bit before to start initiating cutting.

Projects requiring a sink cut-out can be an obstacle many fabricators dread. Since we already know plunging is not the ideal way to go about this, what are your options? When preparing a sink cut-out, it is advised to drill each of the four corners with a 1/2” core bit before to start initiating cutting.

PORCELAIN FOR YOUR HOME, TILES

Ceramic tiles are thin pieces made of clay, silica, fluxes, dyes, and other raw materials to create floors and/or walls.…

Read More

PORCELAIN FOR YOUR HOME, COUNTERTOPS FOR YOUR KITCHEN

Due to its great demand, porcelain kitchen countertops are becoming more sophisticated and have greater hardness

Read More

DEKTON FOR YOUR HOME, FLOORS, AND PAVEMENTS

Large format and minimal joints. Dekton allows you to create outdoor and indoor floors with great visual continuity and maximum…

Read More

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34